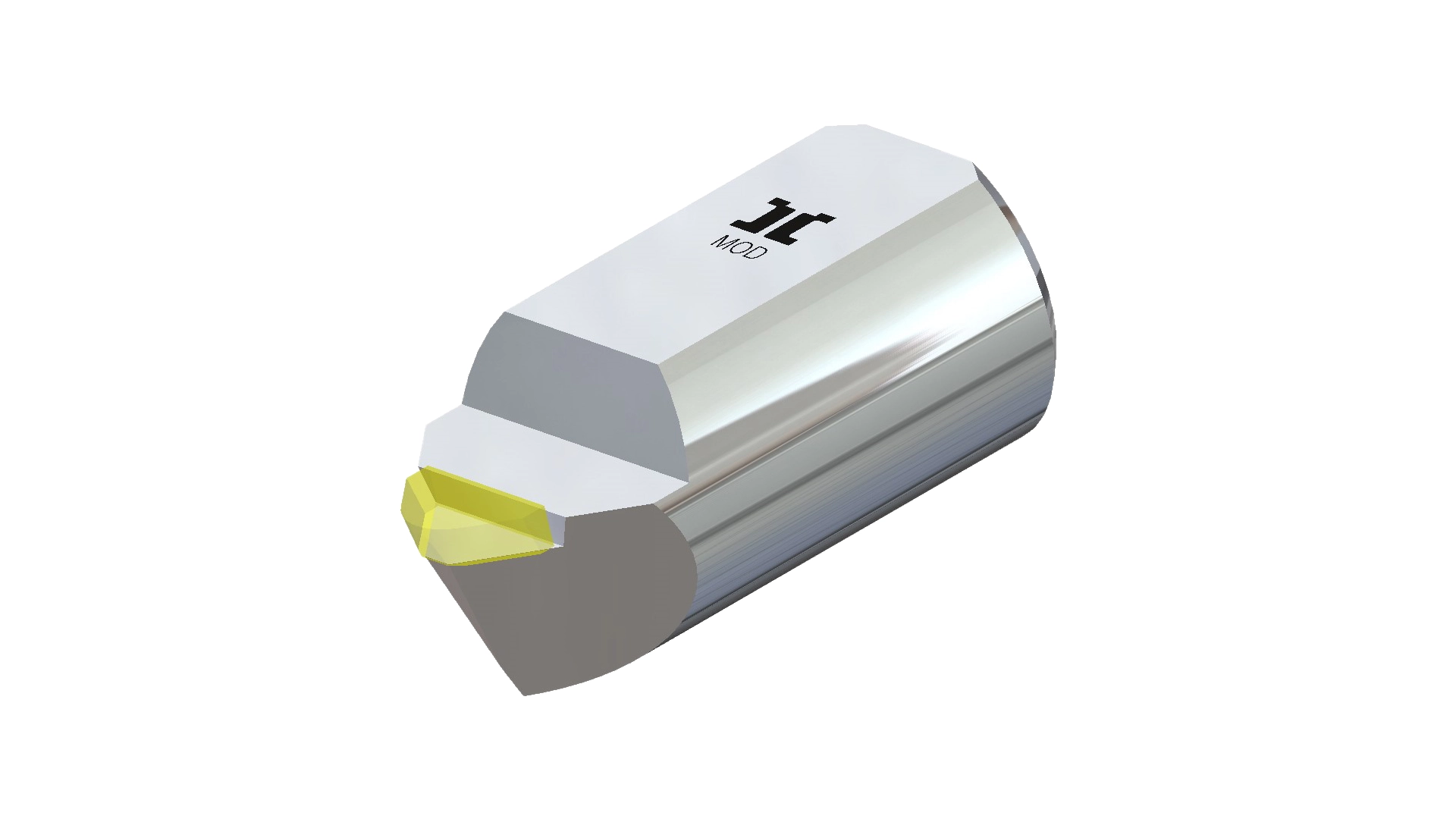

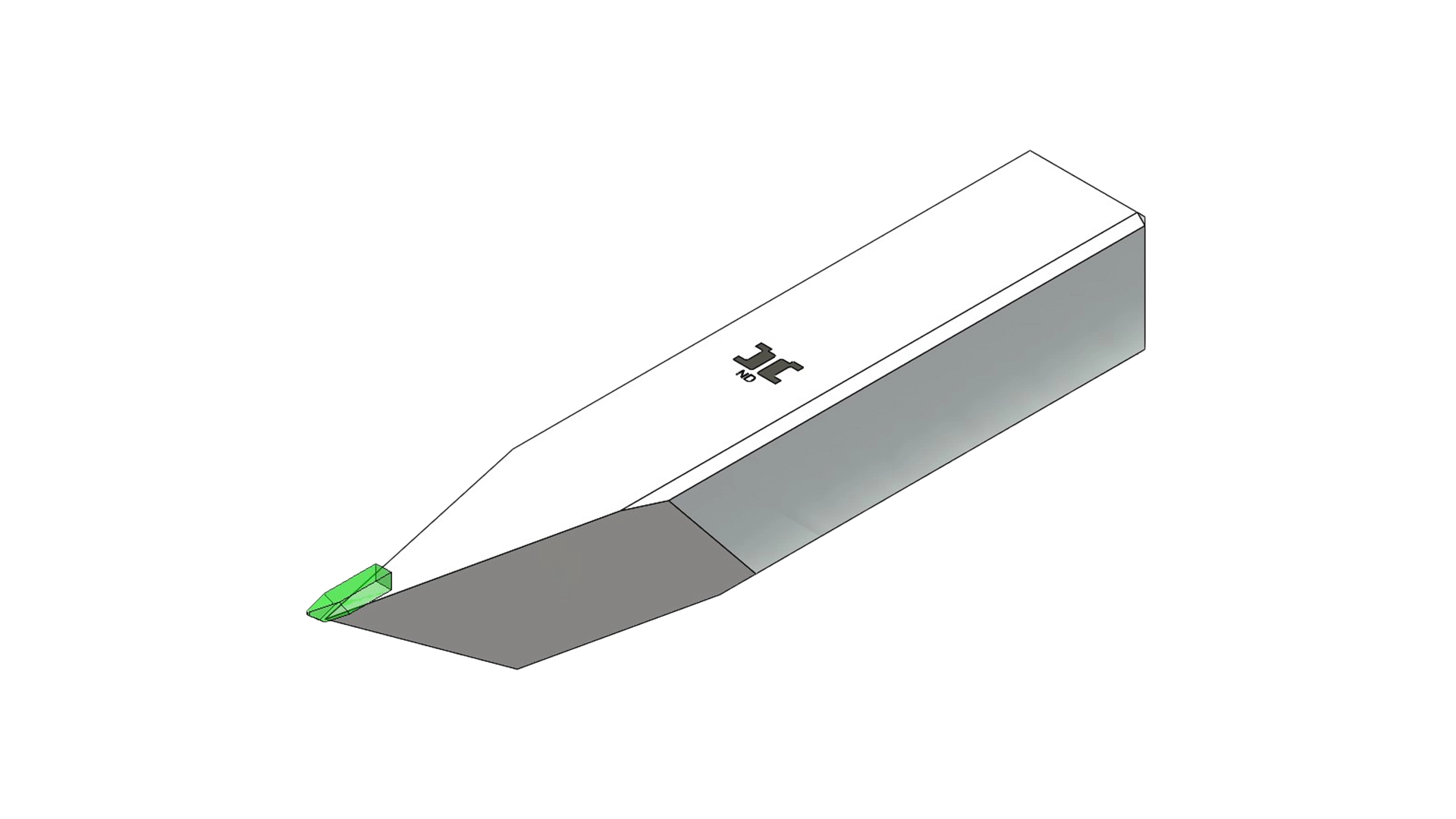

Single Crystal Diamond (SCD) Cutting Tool

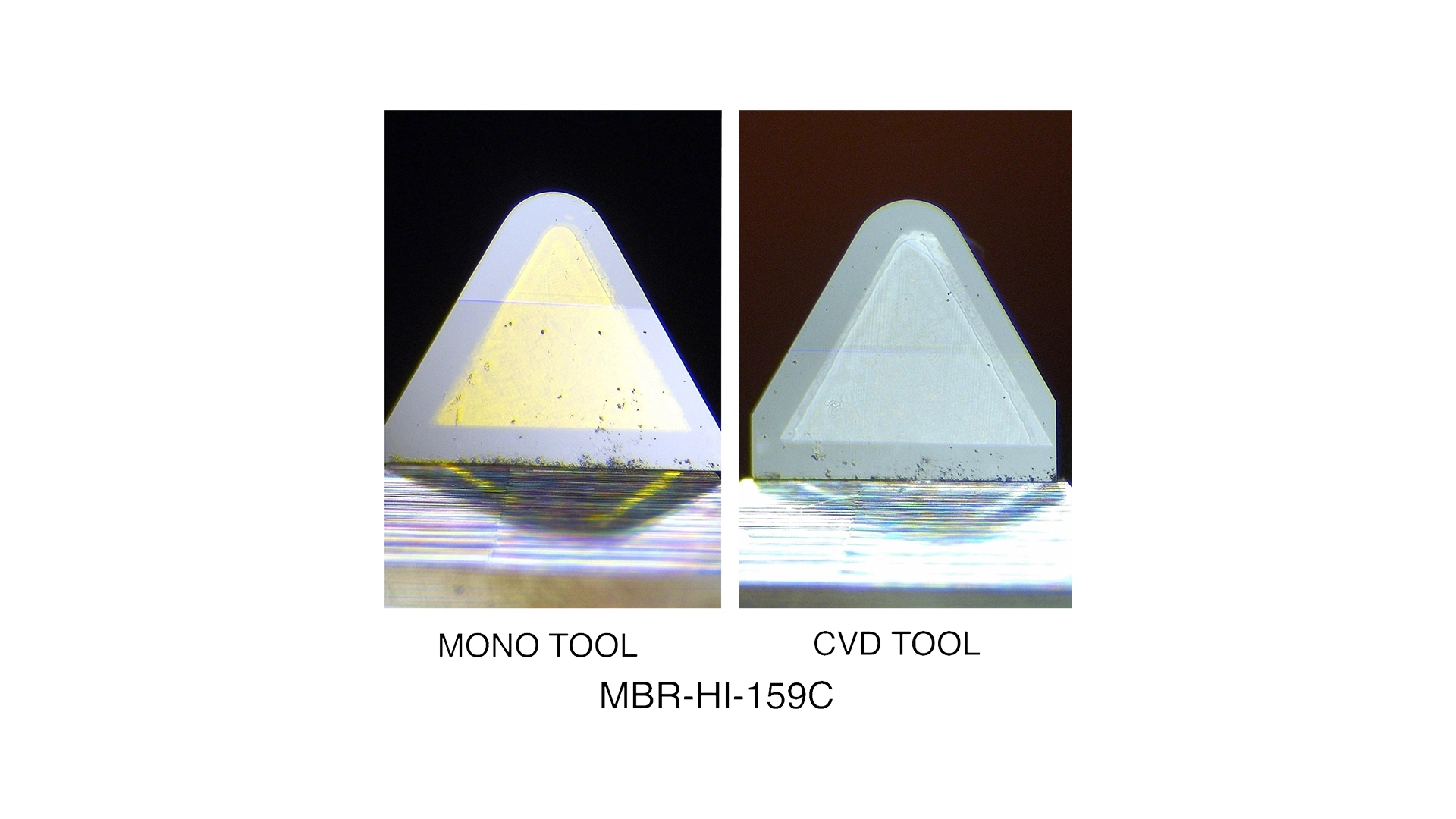

Single Crystal Diamond (SCD) Cutting Tool has a cutting edge made of single crystal diamond, which can be categorized into 3 types: Monocrystalline Diamond or “MCD”, Chemical Vapor Deposition Diamond or “CVD”, and natural diamond or “ND”. These are considered the hardest materials known to man, giving a tool the strength to perform better and longer compared to PCD in some applications. Unlike PCD, SCD is able to achieve mirror-like surface finish on the workpiece. They are superior in heat and wear resistance, which is suitable for cutting and machining hard and/or abrasive materials (grinding wheel materials, ceramic, glass, etc.) as well as high-precision parts.

The most notable benefits to SCD cutting tool is the achievable surface finish. It can eliminate grinding or polishing process in machining of non-ferrous materials. Especially in miniature parts (e.g. jewelry and watch components), where grinding is not possible and polishing is highly labor-intensive.

The superior characteristic is because SCD is one solid crystal of diamond, as the name suggests. PCD is a composite material with diamond particles held together with cobalt-based binder. And during the cut, the much harder diamond particles remove the material, while the area between diamond particles that is the binder creates microscopic surface imperfections. Hence, SCD can produce a surface finish that is impossible with PCD.